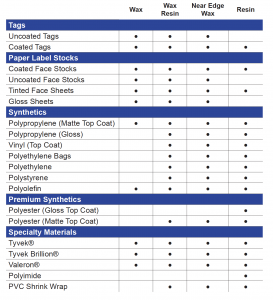

Ribbon Types

Wax– Wide media performance, for coated papers, matte synthetics, and poly bags. Excellent durability.

Wax Resin– Wide print range. For paper, polypropylene, and polyester.

Near Edge Wax– High and low-speed printer performance. For data coding and barcoding, film, and paper.

Resin– Wide substrate range. General-purpose Resin. Excellent durability with low print energy.